COLOR CODE

WHAT IS COLOR CODE IN THE INDUSTRY?

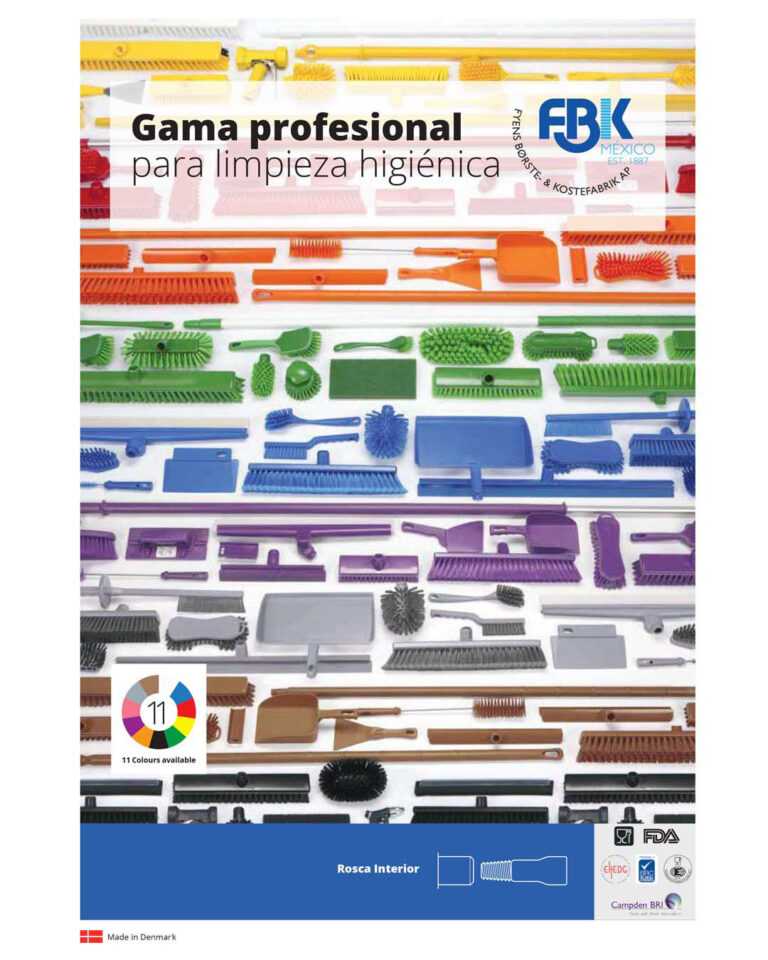

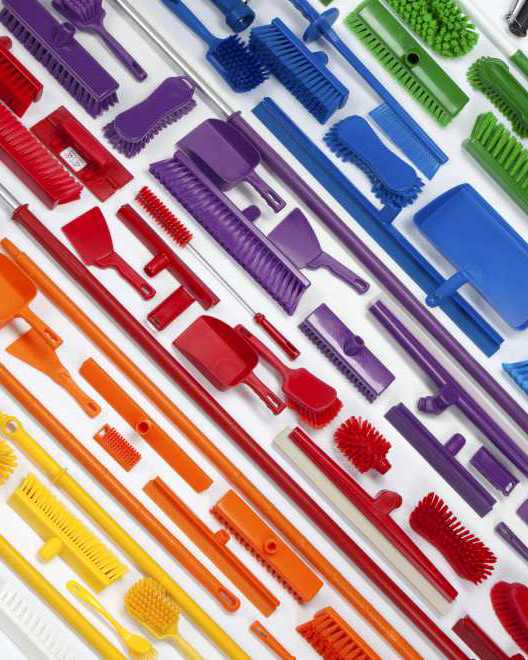

The color code is the use of implements of a specific color for each productive area.

WHAT IS COLOR CODING USED FOR?

- The purpose is to guarantee safe and quality food to everyone and everywhere.

- The Codex General Principles of Food Hygiene (BPA/BPM) apply to the entire food chain, from primary production to the final consumer, and establish the hygienic conditions necessary to produce safe and healthy food.

COLOR CODE USE TIPS

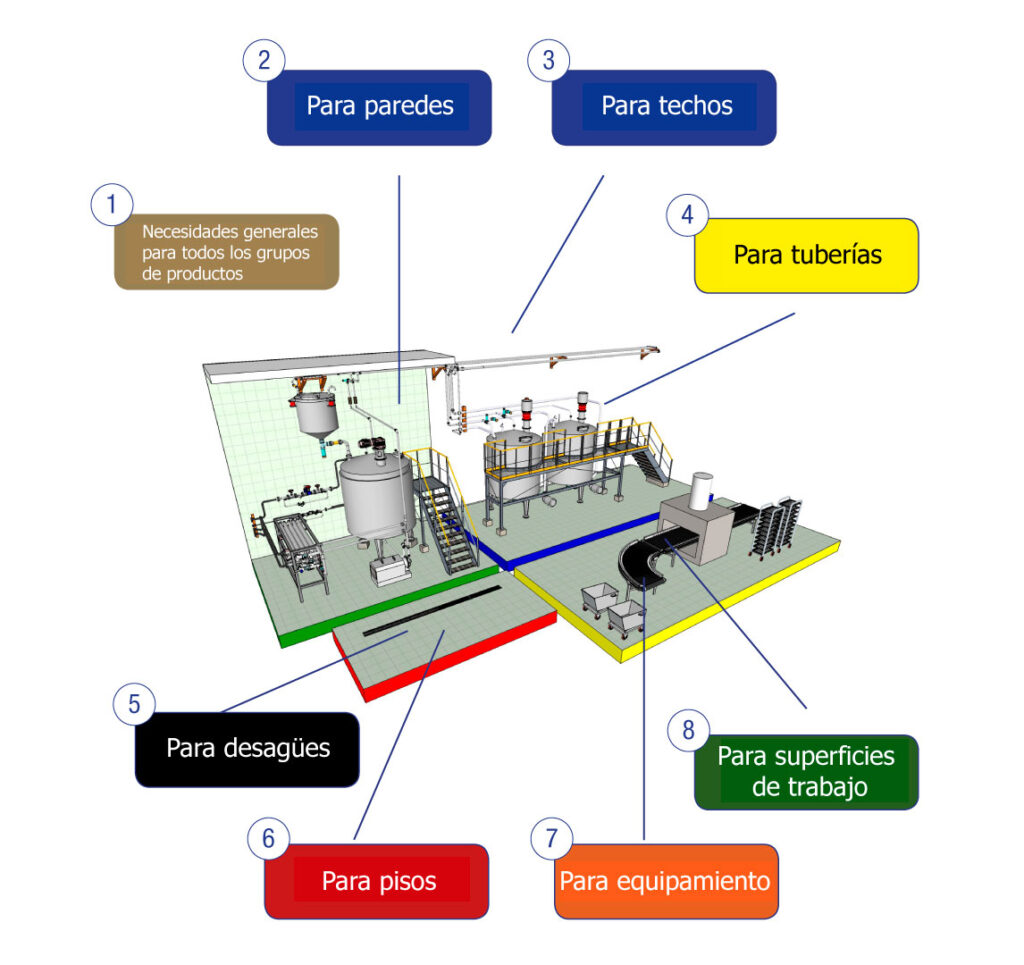

Implementing a reliable color coding system for cleaning supplies in your business is an easy way to prevent cross contamination and identify bad practices.

1. Keep it simple: Avoid using complicated colors on the industry. Encode by zone or by process.

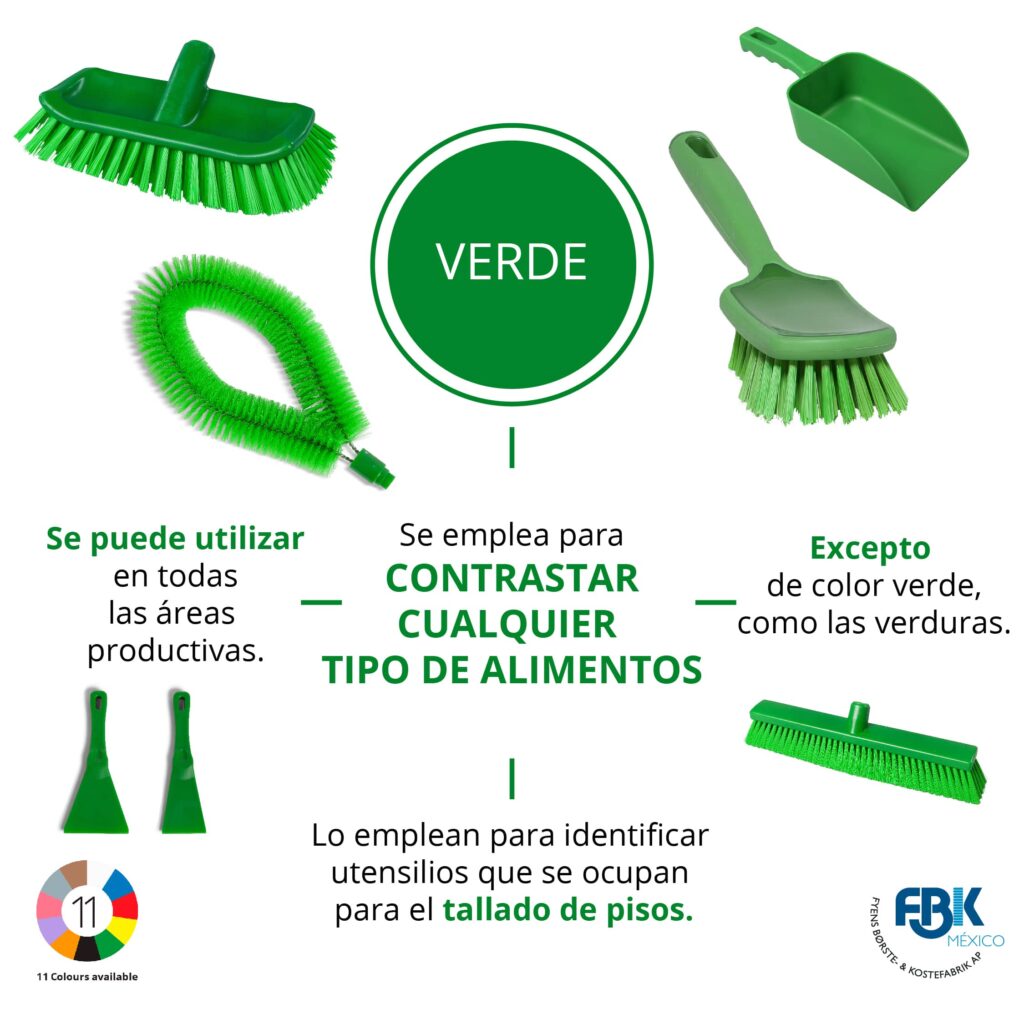

2. Use logical colors: Use a color contrary to the product you manufacture.

3. Make the use of color very clear: Use signs and shadow boards for identification and organization.

4. Communicate your color code: Train your team in the proper use of the color code.

5. Remember that: With the system you can prevent cross-contamination, cleaning processes become faster, more organized, efficient and you save resources.

Create a plan that works. We recommend that you regularly monitor and re-evaluate your color code plan as well as inspect your food handling tools and cleaning equipment to prevent cross contamination.

- Identifyng risks

It will depend on the food, its susceptibility, the processes followed and even the legal requirements.

- Depending on the material handled

Differentiate the types of raw material and their risks, assigning a color to each of them.

- Depending on the process

By “virtually” separating the stages of production or management by colors, we prevent cross-contamination problems.

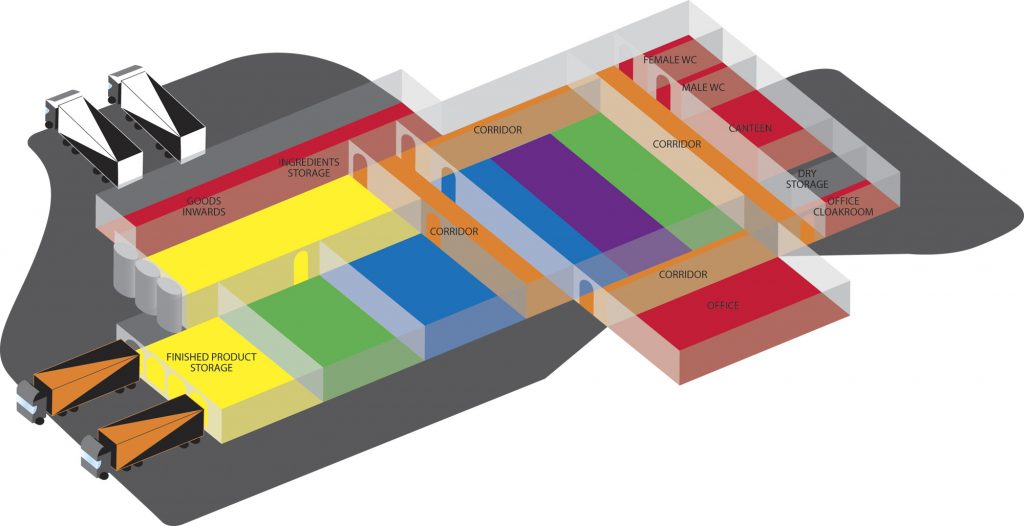

- Depending on the area

To apply this strategy it is necessary that the zones are previously differentiated with a logical and specific criterion.